FSDU Design and Manufacture to Promote, Enhance, and Sell Your Brand and Products

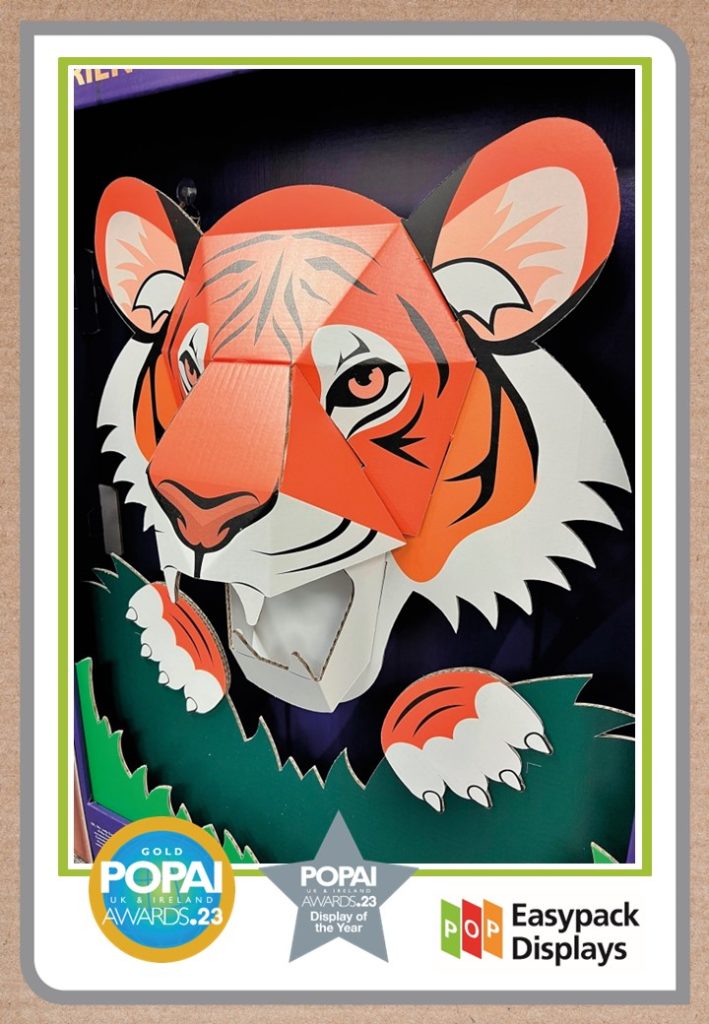

The dedicated, on-site manufacturing facilities at Easypack Displays have a history rich in designing and manufacturing Free Standing Display Units (FSDU) for retail. Their exceptional ability to design, print, manufacture, co-pack, and distribute units that, importantly, sell product, means that Easypack’s corrugated cardboard 3D temporary displays for the retail sector are one of the most effective and valuable tools in promoting goods in-store.

The design studios and factories at Easypack Displays are equipped to produce the full range of corrugated cardboard 3D temporary display units, from functional quarter pallet display units and merchandising units through to large, complex theatrical display units – and everything in between.

The extensive experience Easypack has working with innovative retailers means that the knowledge is possessed to create your ideal display units to showcase your products. As Easypack Displays offer an end-to-end service, they can ensure your display units will be protected throughout the supply chain and adhere to retailer guidelines, so it will be right the first time.

The Easypack team will help you every step of the way to ensure that, together, we create exceptional temporary display units to merchandise yours or your customers ‘ product, and make sure they are seamlessly delivered to stores ready to sell through.

Discover more about how Easypack Displays can help you achieve your sales objectives with temporary display units.

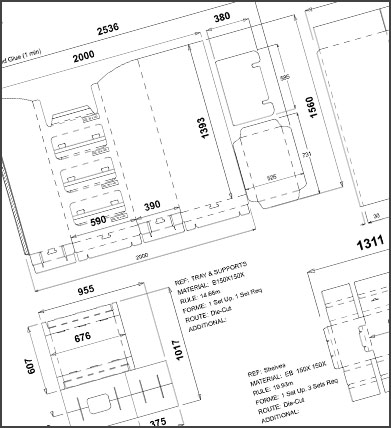

Design Development

Great display stands come from a strong understanding of graphic and structural design. Visual appeal is vital, as is maximising capacity and stability. All of which contributes to developing cardboard displays that attract shoppers, sell product, are space efficient, and profitable.

Product

Every cardboard display is manufactured to ensure your products are given the prominence in-store they deserve. All stands are engineered to remain stable as well as still look good after being subjected, often for several weeks, to the rigours of a demanding retail environment.

Co-packing

With a full co-packing facility that has the space, flexibility and experience to co-pack and dispatch your products to store, you can be positive they’ll be ready to go straight to the shop floor and be selling within minutes of being delivered.

Easypack’s Company Guide

You have so many display options available, it’s often helpful to be able to skim through a well laid out guide to help you bring practical, sustainable innovation to your in-store displays.

Case Studies

It’s always difficult to know which case studies might best help you achieve your objectives and so what to include, however here are a few we hope you find useful.

Social Media

Constantly updated with informative and interesting content.